From the design to the shape: To the point and perfect in every detail.

The design, function, material and cost-effectiveness are the core terms of our tool manufacturing and die construction. CB projects, designs and produces its own tools and fixtures.

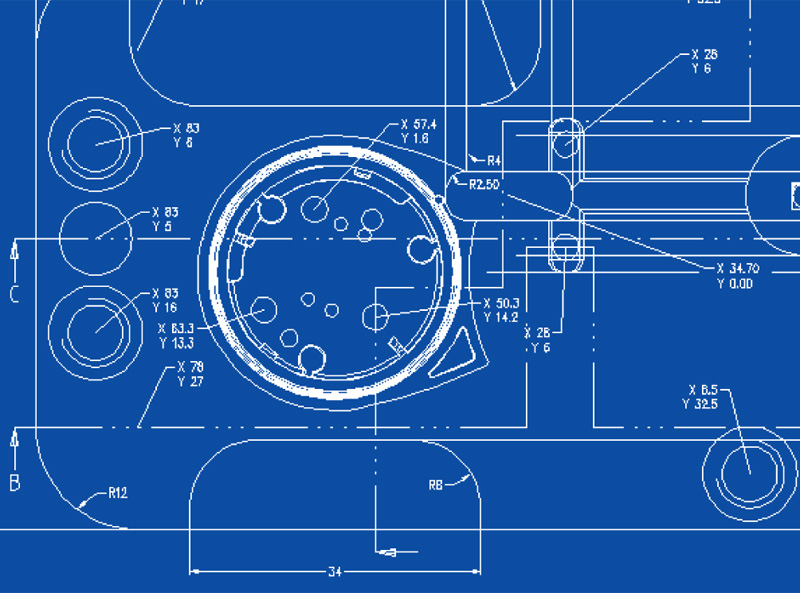

The performance diversity spans from simple to complicated, from test dies to high performance tools, from small short runs to large lots. We cover a wide assortment in product design with the combination of metal and plastics. Dies and tools are completely produced by modern CNC-controlled processing and eroding machines. A seamless data transfer and a flexible and efficient conversion into finished tools is enabled by the integration and coupling of CAD/CAM to production facilities in 2D AutoCAD and 3D Solid Works.

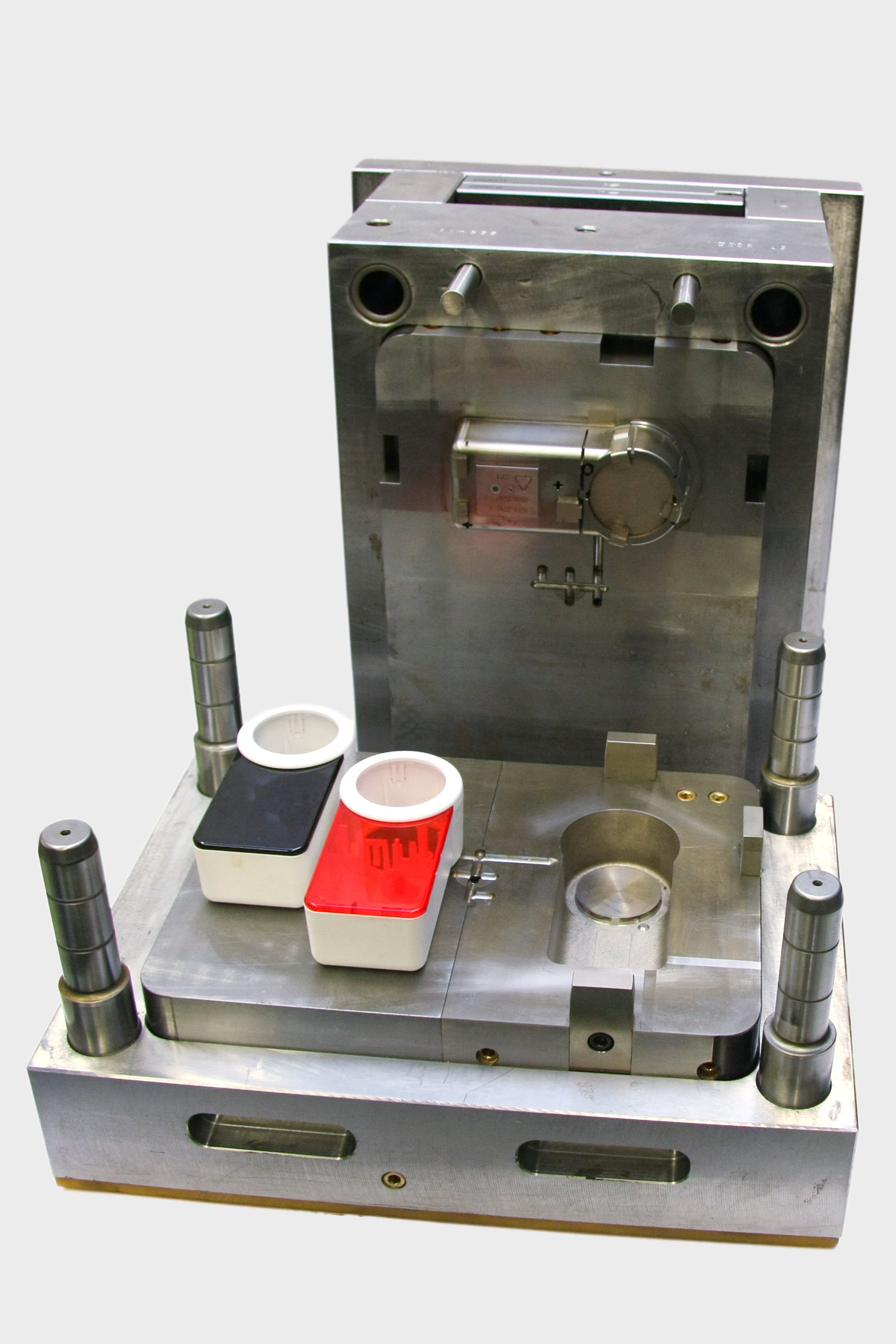

Experience, established processing knowledge and high quality Tool and Mold Making Department form the basis of producing dies for precision injection molding, complete cuts, successive compound tools, stamping and bending dies and assembly fixtures of a striking quality and precision. This also applies for the production of prototypes, zero and small series. We inspect measure and test the dimensional and form accuracy as well as the perfect function after every production process.

- Measurement results are documented, sample parts are archived.

- The maintenance and repair of implemented production tools are an integral service part.

We transfer our expertise: Our in-house training in tool manufacturing forms the foundation for qualified and motivated specialized work force.